Gas Automation using FinePointe WBP Controller

Some research applications require the generation of specific environmental conditions inside a whole body plethysmograph (WBP) such as hyperoxia studies that simulate an oxygen enriched environment. The FinePointe WBP controller offers four gas port connections supporting such studies. Using FinePointe software, study protocols are created to automatically control internal valves of the gas automation ports by opening and closing them in a user defined manner.

Note: Gas automation ports are opened and closed one at a time. As one port opens, the remaining ports are closed. The port in use delivers the supplied gas to all plethysmographs connected to the controller.

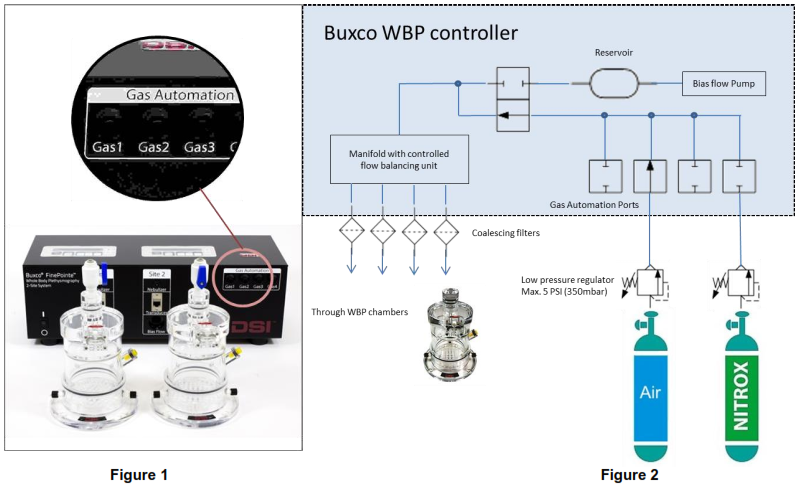

Figure 1: Gas automation ports on FinePointe WBP Controller

Figure 2: Example with 2 gas tanks connected and depicting the flow delivery method through the WBP Controller

Tubing: The tubing that we purchase internally for this purpose is part number 1D-025 from this sales sheet: https://www.freelin-wade.com/documents/Fre-Thane_Polyurethane.pdf

Example Study design: Certified laboratory gas tanks (equipped with low pressure regulators) are connected to the gas automation ports on the WBP Controller. During baseline, fresh air is provided to the animals using the internal bias flow pump (normoxia). Following baseline, bias flow is turned off and one gas automation port is opened to create the desired environment in the plethysmographs. The gas is delivered through the controller’s internal manifold and flow is regulated to each plethysmograph connected to the controller using variable valves. After a user specified time, the gas automation port closes and the internal bias flow pump resumes. The flexibility of FinePointe software allows researchers to alternate between room air and gas tanks in a variety of configurations.

Comments

0 comments

Please sign in to leave a comment.